Manufacture of six well jumpers on the Moho field in Congo

Since late 2023, Friedlander Industrie Congo has been involved in the fabrication of six subsea jumpers as part of the extension of the offshore field operated by TotalEnergies EP Congo.

This is a major manufacturing challenge for the fifty workers operating on this offshore field development project, which is scheduled to run until summer 2025.

The multi-bore well jumper and the five 6-inch mono-bore ones are prefabricated at Friedlander Industrie Congo workshop (23,000 m²), then finalized, painted, tested and insulated on a 4,000 m² dockside area at the ILOGS port. The first well jumper was loaded onto the Neptune barge on December 29, 2024.

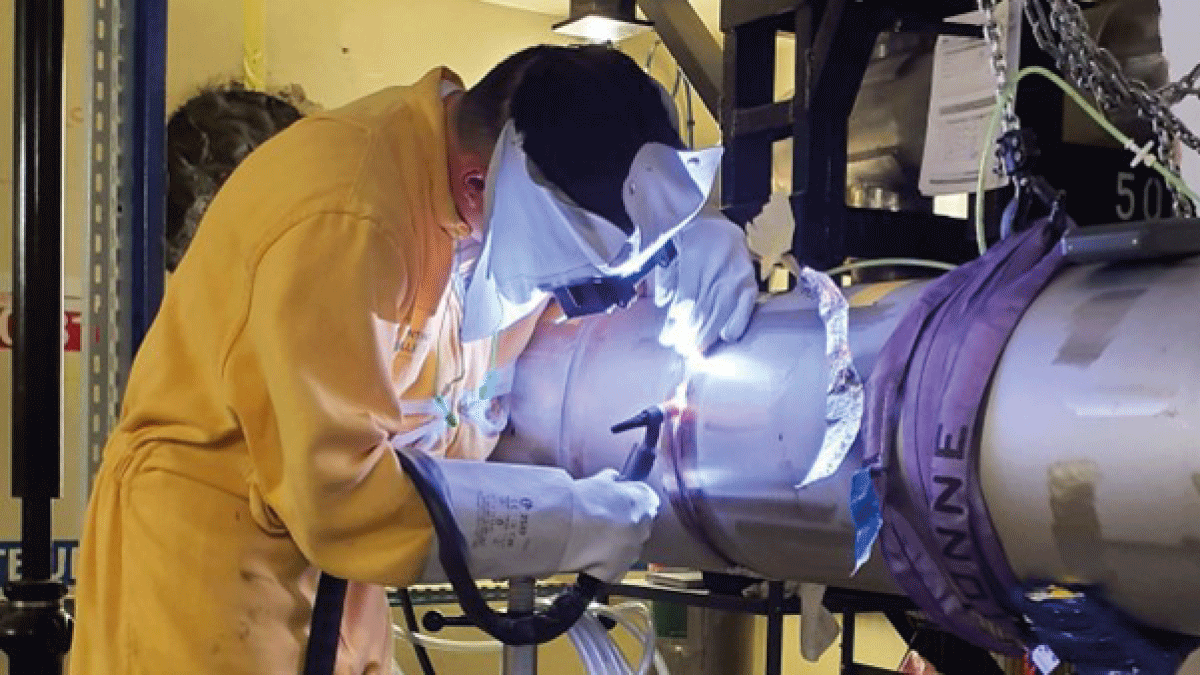

“This demanding project, both in terms of quality and dimensional tolerances, requires significant involvement from our teams” says Lionel Vignes, Head of Bids at Friedlander International. Numerous skillsets are being deployed: complex welding, stringent quality checks, painting, insulation, lifting operations, hydraulic testing and more.

Beforehand, the first half of 2024 was dedicated to a major qualification phase to define the welding procedure. “The precision of our teams during each successive and sometimes critical task, along with the effective management of simultaneous activities, are key to the success of this project” explains Yohann Lecossois, Deputy Project Manager on this assignment.

Qualified local resources

To be operational quickly, Friedlander Congo rehired teams who had previously delivered well jumpers between 2015 and 2018. Additional support from other Friedlander entities has also been brought in for construction management (Ghana), HSE missions and seafastening (Cameroon). The fabrication of the first well jumper required around-the-clock shifts.

Each of the six well jumpers – measuring 40 to 60 meters long and weighing around 40 tons – requires up to three different spreader beams, depending on the configuration. These assemblies (jumper, rigging and spreader) require lifting by a 450-ton crane.

The first year of the project was successfully completed with a zero-incident record. “Everything is being done to maintain this level of HSE performance through to project completion, thanks to the unwavering commitment and determination of our field teams who prioritize safety for everyone, clients, subcontractors and partners alike” affirm Lionel Vignes and Yohann Lecossois.

The six subsea jumpers will be installed in the Moho Nord area, an extension of the Moho offshore field that will connect four new wells to the existing networks. This development is expected to add 17,000 barrels per day to current production capacity.