Modernizing a large-scale furnace in the steel industry

As part of the furnace replacement at the Comilog Dunkerque steel production facility in Gravelines, Friedlander Dunkerque manufactured and installed the primary duct network and a cooling unit. A total of 250 tons of structural steel was used.

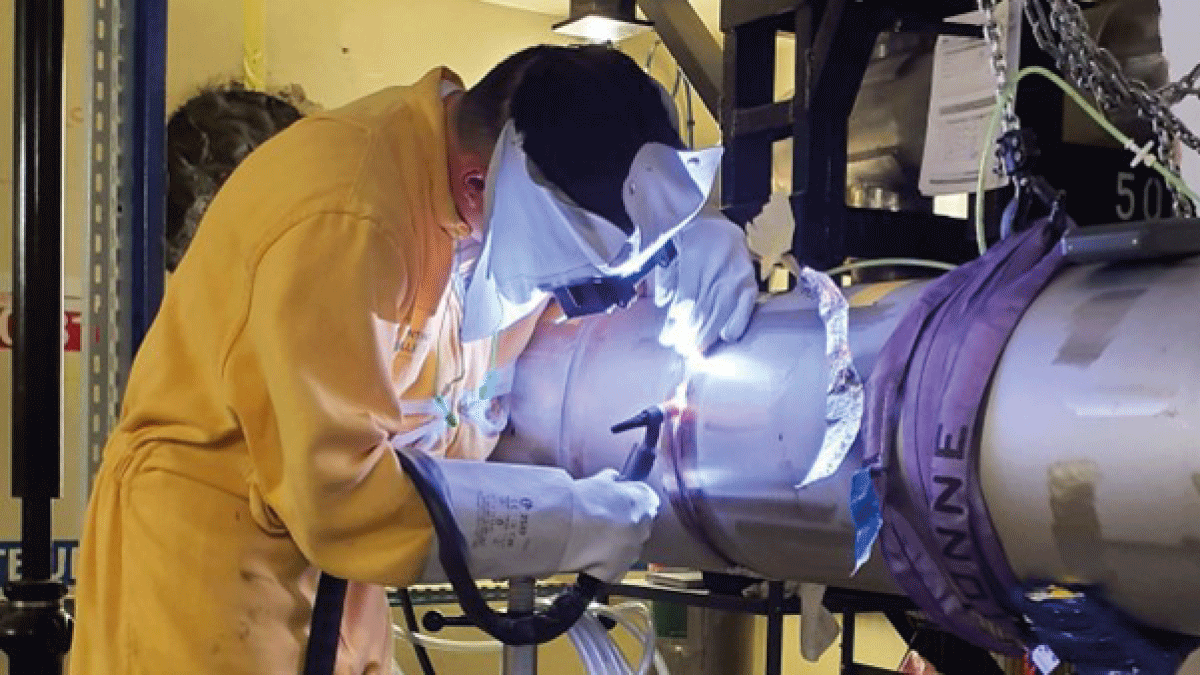

This project required the extensive deployment of teams specializing in boiler-making, assembly (ductwork and supports) and lifting, both in the workshop and on-site at Comilog Dunkerque’s silicomanganese production facility in the Hauts-de-France region.

The furnace is used to reduce manganese ore and transform it into silicomanganese, a steel additive essential to numerous industries including automotive, construction, shipbuilding, aerospace, rail, and more. “This was a highly technical project, especially given the size of the components” noted Yann Lefrançois, Deputy Branch Manager.

A strategic entry into the heavy industry sector

A 650-ton capacity crane was deployed on-site to lift parts weighing up to 100 tons, with a reach of 42 meters and a height of 35 meters. Rigorous planning and strong partnerships ensured the safety and success of the operations, as well as full control over deadlines and costs.

This project has enabled Friedlander Dunkerque, which specializes in engineering, new works (piping, boiler-making) and maintenance, to position itself as a key player in large-scale industrial projects, helping clients modernize their facilities and processes.