Home > Newsroom > Feature articles > Remediation: innovating to break down PFAS

Remediation: innovating to break down PFAS

In response to increasingly stringent regulations targeting these so-called “forever chemicals,” widely used in many industrial processes, the teams at Ortec-Soléo’s Meyzieu laboratory have accelerated their R&D efforts. This work has led to the filing of a patent for a low-temperature catalytic thermolysis process capable of degrading PFAS molecules more efficiently than existing solutions, while significantly reducing CO₂ emissions.

PFAS: widespread uses, complex degradation

PFAS (Per- and Polyfluoroalkyl Substances) are a broad family of several thousand chemical compounds. They are defined by the presence of at least one carbon–fluorine (C–F) bond, one of the strongest and most stable bonds in organic chemistry, giving PFAS exceptional resistance to heat and chemical reactions. Their molecular structure gives them both hydrophilic properties (acidic head) and hydrophobic/lipophilic properties (C–F tail).

These highly valued characteristics have led to their widespread use since the 1950s across numerous sectors, including:

- Firefighting foams

- Non-stick coatings (cookware, textiles)

- Food packaging

- Waterproof textiles

- Electrical products and cosmetics

However, this same chemical stability is what makes PFAS so problematic today, as it severely limits their natural degradation in the environment.

A challenge for owners of impacted sites

Because PFAS degrade extremely slowly and are present in many everyday products, they have spread widely throughout the environment, contaminating water, soils, sediments and living organisms, and accumulating in the human body.

According to a December 2024 study by the European Environment Agency, between 51% and 60% of European rivers exceeded environmental quality thresholds for certain PFAS between 2018 and 2022. Their persistence, combined with increasing public awareness and regulatory pressure, presents a major challenge for owners and operators of contaminated land.

PFAS remediation: current state of play

As a recognized expert in environmental remediation, Ortec-Soléo is regularly called upon by clients facing PFAS contamination, particularly during site rehabilitation projects requiring the elimination of these substances.

To date, several techniques have been implemented by Ortec-Soléo teams:

- Pumping and treatment using activated carbon or resins

- Foam fractionation / air stripping

- Soil washing

- Stabilization

- Thermal desorption

While these processes can extract PFAS, many are costly, energy-intensive and time-consuming due to the high temperatures involved. Truly destructive technologies, those that actually break down PFAS molecules, have remained difficult to implement at scale, as they rely on extremely energy-intensive and expensive processes (incineration > 900°C, sonolysis, supercritical oxidation, etc.).

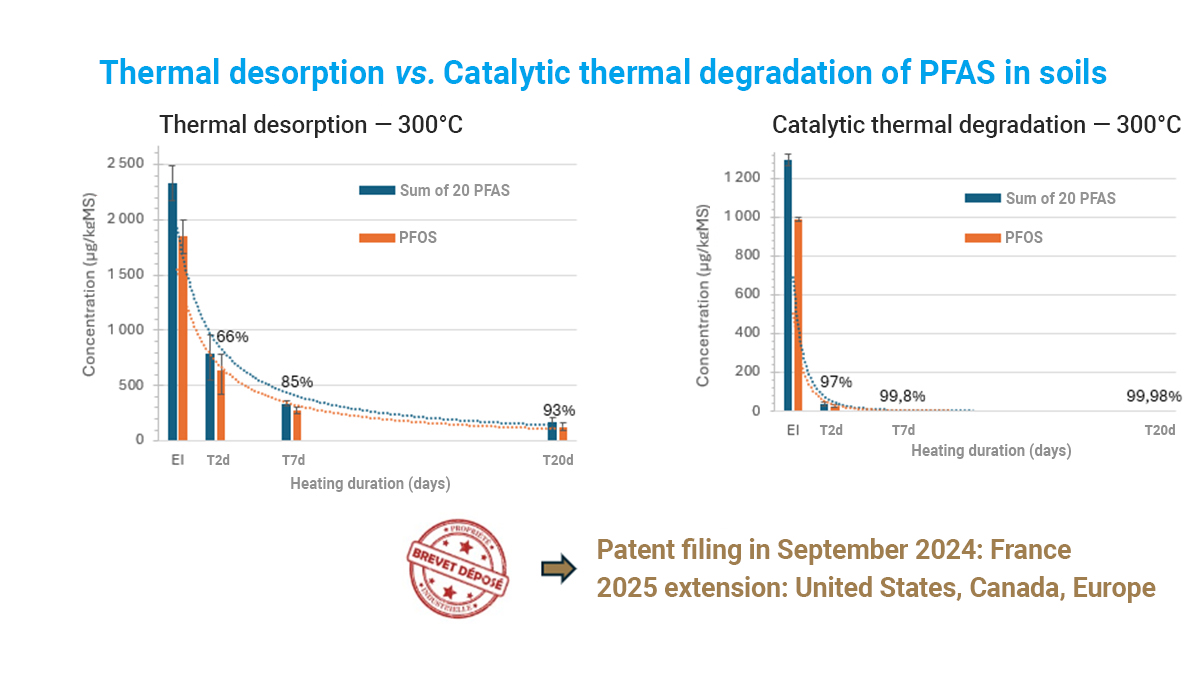

A patented breakthrough: low-temperature catalytic thermolysis

An ambitious R&D initiative conducted at the Ortec-Soléo laboratory in Meyzieu has recently led to the filing of a patent for a new PFAS management, treatment and degradation process, deployable both on site and in situ, based on low-temperature catalytic thermolysis (250°C). Unlike conventional thermal desorption, this innovation enables actual degradation of PFAS molecules, with the release of fluorides.

By combining heat with a specific reagent, catalytic thermolysis breaks the carbon–fluorine bond, the root cause of PFAS persistence. The ability to initiate degradation at temperatures as low as 250°C significantly improves the carbon footprint of remediation operations while reducing treatment duration and overall energy demand.

A nationwide

Leveraging its nationwide network of agencies, laboratories and treatment facilities, the Ortec Group provides comprehensive remediation of contaminated soils and groundwater through Ortec-Soléo, as well as soil management through dedicated platforms (Valorterre, Biogénie). These integrated infrastructures ensure end-to-end control of PFAS management across the entire treatment chain.

At Valorterre and Biogénie platforms, PFAS-impacted materials (up to 50 mg/kg) are sorted and consolidated for secure, local handling before being directed to the most effective disposal pathways or treated directly on site.

This innovation was presented at the latest Pollutec trade show, where it generated strong interest among industrial stakeholders, particularly as PFAS regulations are expected to evolve further in 2026.

_____

In the early 2000s, initial studies revealed the widespread presence of certain PFAS in the environment and in human blood. Since then, regulations have continued to tighten, culminating in a major European proposal in 2023 to restrict all PFAS.

On February 27, 2025, French Law No. 2025-188 established a framework for PFAS management in France, setting a regulatory threshold of 0.1 µg/L for the sum of 20 “priority” PFAS.

Effective January 1, 2026: Ban on the manufacture, import, export and sale of products containing PFAS, including cosmetics, ski wax, clothing and footwear (and their waterproofing treatments), with exceptions for protective equipment (military, firefighters, etc.).

Effective January 1, 2030: This ban will extend to all PFAS-containing textiles (furnishings, etc.), with exemptions to be defined by decree for certain industrial technical textiles.

Administrative penalties will apply in cases of non-compliance.

Discover the Feature Articles

Remediation: innovating to break down PFAS

Ortec-Soléo secures a patent for a high-performance, low-temperature catalytic thermolysis process to break down PFAS.

Bingo Extension

The “Bingo Extension” project responds to a desire by the Burkinabe National Hydrocarbons Company to double the storage capacity of the depot and to modernize its facilities.

Diesel d’Ultime Secours (DUS)

The Ortec Group has mobilized a dedicated team for the manufacture and installation of 36 Diesel d’Ultime Secours in France.