Orsen contributes to the development of a new energy hub in Africa

Orsen is actively involved in two key phases of the GTA liquefied natural gas project. Leveraging its offshore and subsea expertise, the company is supporting the development of one of West Africa’s largest gas reserves.

In 2016, exploratory drilling confirmed the presence of a major gas field along the maritime border between Mauritania and Senegal, located 120 kilometers offshore at a depth of approximately 2850 meters. This led to the launch of the Grand Tortue Ahmeyim (GTA) project, spearheaded by BP, Kosmos Energy, the Société Mauritanienne des Hydrocarbures (SMH), and the Société des Pétroles du Sénégal (PETROSEN). This future energy hub will be the deepest subsea infrastructure in Africa, with the capacity to produce 2.5 million tonnes of liquefied natural gas (LNG) annually for over 20 years.

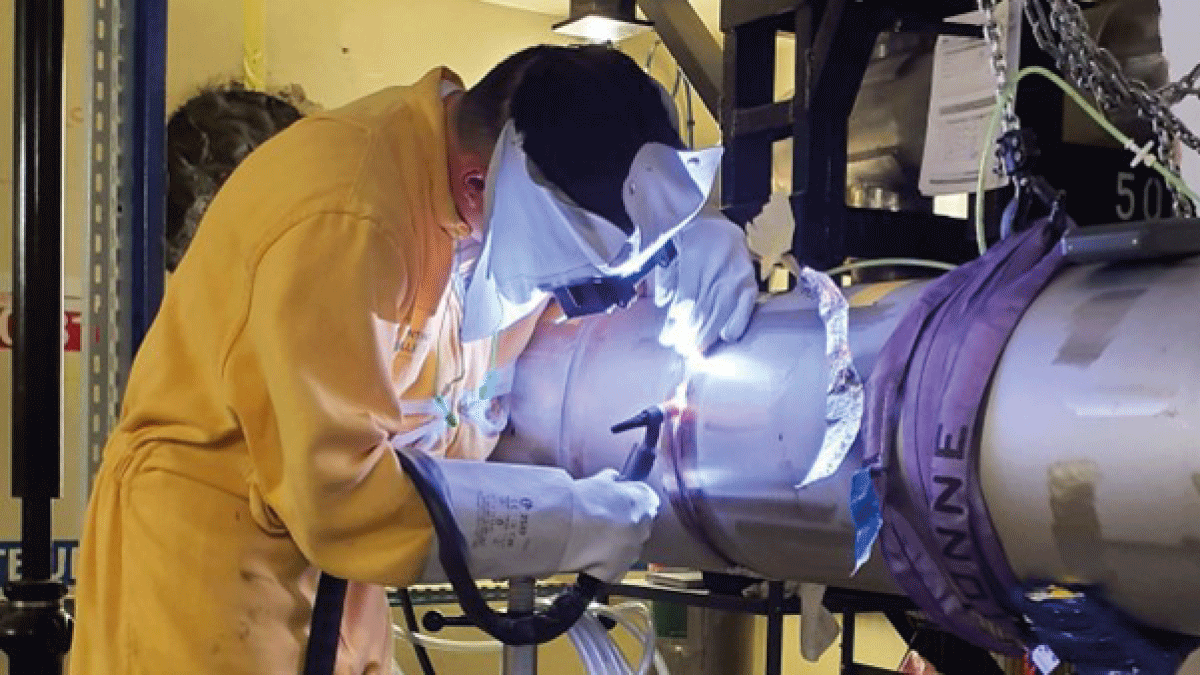

Orsen is taking on two key tasks in the GTA project: manufacturing 18 subsea pipeline spools and carrying out metallurgical work on a floating production storage and offloading (FPSO) unit. This unit will process natural gas before transferring it to a floating liquefied natural gas (FLNG) unit, where it will be liquefied for easier transport.

New operations aboard an FPSO vessel

Built at a shipyard in China, the GTA FPSO embarked on a long journey in January 2023, reaching Senegal in June 2024 after passing through Singapore, Mauritius, South Africa, Mozambique, Namibia, and the Canary Islands. More than 120 Orsen employees, including welders, painters, electricians, mechanics, crane operators, and seafarers, have successively boarded the FPSO to carry out new work. For some of them, it was their first offshore experience.

“We have developed expertise that is now widely recognized. Thanks to strong teamwork, we successfully met the expectations of both the country and our direct client, Technip Energies,” says Simon Gire, Orsen Project Manager.

Manufacturing of 18 spools

Orsen teams have been performing spool welding since 2023. “We were already experienced in subsea work, having just completed a similar project. The automatic skills acquired by our welders enabled us to qualify the welding procedures in just six months,” explains Thibaud Michal, Orsen Project Manager. The production of the pipe sections (up to 100 meters long and installed at depths of up to 2800 meters) is carried out at the site of our direct client, Saipem.

These subsea metal structures will be connected to the FPSO unit during a hook-up phase scheduled for next fall. BP plans to start gas field operations by the end of the year.

The seamless execution of these major projects is made possible through the joint effort involving teams from Contracting International, Engineering, International Environment, as well as Welding and O’Métiers services.